News & Media

Contacts

-

Valgro India Limited (HO)

Valgro House, 2nd Floor,

Shailly Square,Virat Nagar,

Ahmedabad, 382415

Gujarat. India - +91 90990 79325

- sales@valgroabrasives.com

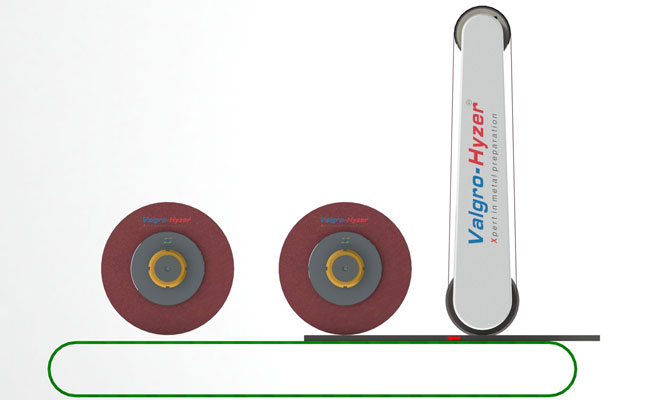

SAMARTH Classic Hybrid Series Deburring & Finishing Machine is suitable for metal finishing and deburring at an affordable price with many standard features. The classic Hybrid series abrasive belt + Roller Brush deburring machine for grinding and Finishing of the final sheet metal and other flat parts. This is an automatic feed-hard machine with a belt, / Roller.

SAMARTH Classic Hybrid Series Deburring & Finishing Machine is available from 150mm to 1600mm with multiple head options. It offers dual infeed and outfeed pinch rolls to ensure parts feed throughout the machine uniformly. It is compatible with a Belt, all these accessories per your industrial requirements. Its thickness measurement control can be between 1mm to 50mm of parts. It can be configured with automatic abrasive belt tracking to ensure proper belt alignment during operations.

| Model – Classic Hybrid Series | HYB 06-2 | HYB 24-2 | HYB 50-4 | HYB 62-4 | ||||

|---|---|---|---|---|---|---|---|---|

| Head Type Belt / Roller Brush / Disc Brush | Belt + RB | Belt + RB | Belt + RB | Belt + RB | ||||

| Work Surface | Top Side | Top SideTop Side | Top Side | |||||

| Process: Wet / Dry | Dry | Dry | Dry | Dry | ||||

| Work head | 2 | 2 | 4 | 4 | ||||

| Application | Sanding + Finishing + Deburring + Scratch Removal | |||||||

| Finish Achieved | No.4 + Brush | No.4 + Brush | No.4 + Brush | No.4 + Brush | ||||

| Burr Classification | -- | |||||||

| Max Width | 150 | 600 | 1250 | 1550 | ||||

| Min. Length | 300 | 1000 | 1000 | 1000 | ||||

| Min. Max Thickness | 1-50 | 1-5 | 1-5 | 1-5 | ||||

| Weight of capacity kg | 25Kg | 100Kg | 300Kg | 500Kg | ||||

| Drum Diameter | 125 | 180 | 180 | 180 | ||||

| Brush Diameter | 225 | 225 | 225 | 225 | ||||

| Abrasive belt Size | 150mm x 2200mm | 650mm x 2200mm | 1300mm x 2200mm | 1650mm x 2200mm | ||||

| Brush Action R = Rotate / O = Oscillate | R+O | R+O | R+O | R+O | ||||

| Conveyor Type R= Roller / B = Belt | Belt | Roller | Roller | Roller | ||||

| Conveyor Bed | -- | vacuum | vacuum | vacuum | ||||

| Conveyor speed MPM Min / Max | 0.5 - 10 | 0.5 - 10 | 0.5 - 10 | 0.5 - 10 | ||||

| Machine weight | 1000kg | 2500kg | 4500kg | 5500kg | ||||

| Dust collector Suggestion | DCS-5 Auto | DCS-5 Auto | DCS-5 Auto | DCS-5 Auto | ||||

| Electrical parameters | The integrated frequency converter allows the machine to work worldwide with all power supply systems and enables smooth start and enhanced motor protection. | |||||||

Polishing is a value-added operation in stainless steel fabrication. The highest possible degree of surface finish is usually desirable