News & Media

Contacts

-

Valgro India Limited (HO)

Valgro House, 2nd Floor,

Shailly Square,Virat Nagar,

Ahmedabad, 382415

Gujarat. India - +91 90990 79325

- sales@valgroabrasives.com

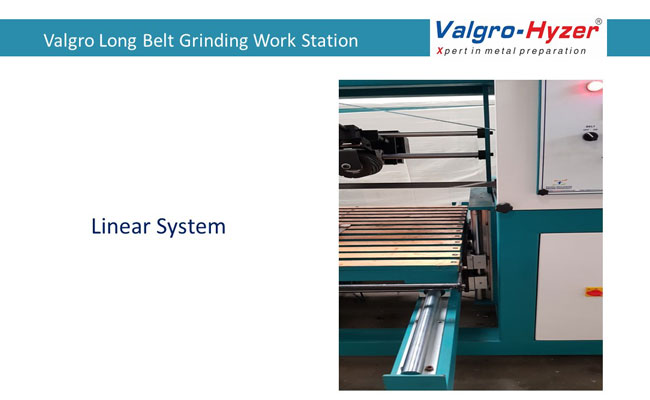

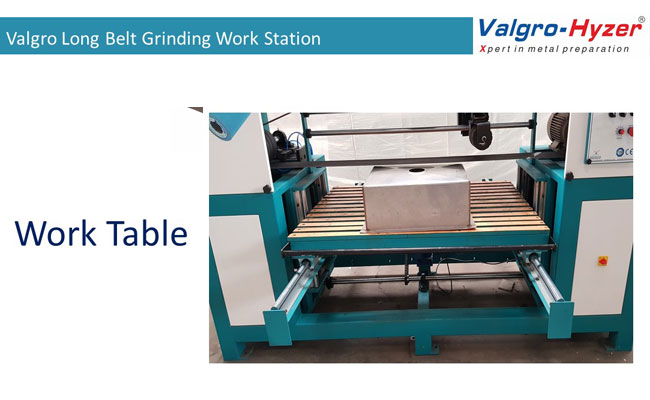

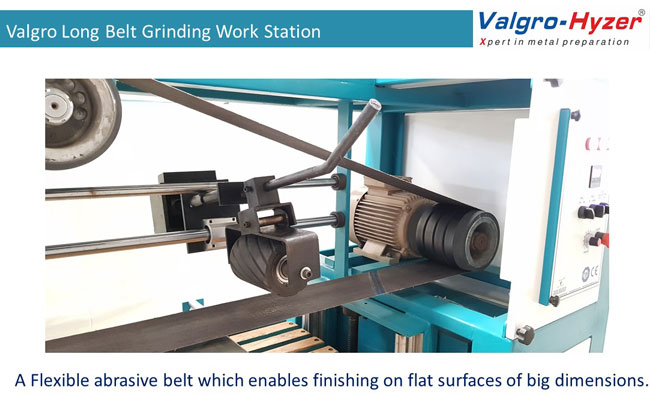

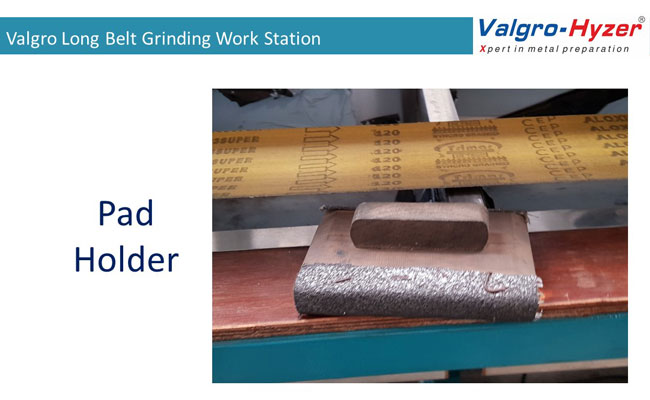

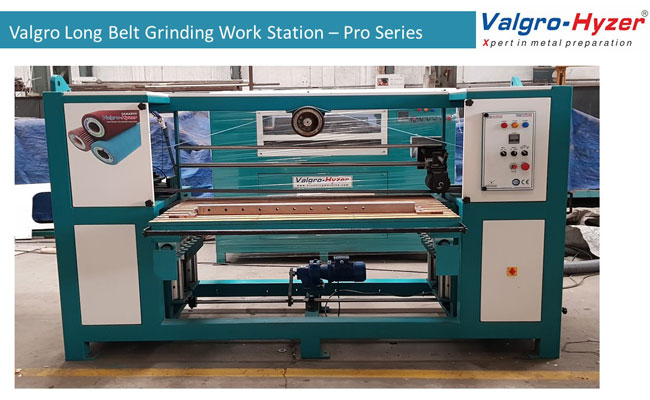

VALGRO long belt finishing machines have a flexible abrasive belt which enables finishing on flat surfaces of big dimensions.

Ideal for Cabinets – Enclosures- panels – Fabrications, Home and Kitchen appliance Industries, Flat surface deburring and Finishing.

Robust design allows the machining of longer workpieces.

VALGRO-LBF machines are available with different working width, with Economic and Professional Series Model with single abrasive belt or Belt and Scotch abrasives roller Brush for Matt and satin finishing.

Ideal for Cabinets – Enclosures- panels – Fabrications, Home and Kitchen appliance Industries, Flat surface of big dimensions. Finishing of Sheet, Laser, Plasma and Waterjet cut parts, Square and Rectangle Tube, Flat product, tubular structures, corners, edges or removing welding from the surface deburring and surface finishing.

| Model | WS-50 Eco | WS-50 Pro | WS-80 Auto | |||||

|---|---|---|---|---|---|---|---|---|

| Head Type | Belt Sander | Belt Sander | Belt Sander | |||||

| Work Surface | Top Side | Top Side | Top Side | |||||

| Work Head | Manual | Manual | Auto | |||||

| Process: Wet / Dry | Dry | Dry | Dry | |||||

| Application | Sandering + Deburring + Finishing + Scratch removal | |||||||

| Finish Achieved | Matt #4 | Matt #4 | Matt #4 | |||||

| Scotch Head | -- | -- | Option | |||||

| Type of Material | Stainless Steel | Stainless Steel | Stainless Steel | |||||

| Working Width | 1250 | 1250 | 3000 | |||||

| Working Length | 900 | 900 | 1550 | |||||

| Working Thickness | 300 | 300 | 300 | |||||

| Abrasives Belt Size | 125 | 125 | 125 | |||||

| Part Holding | Table Top | Table Top | Table Top | |||||

| Abrasives Head Workin | Manual | Manual | Auto | |||||

| Table working | Manual | Manual | Auto | |||||

| Table working Height | 850 | 850 | 850 | |||||

| Dust Extraction : Valgro-Duklean | DCS-3 | DCS-5 | DCS-5 APS | |||||

| Electrical parameters | The integrated frequency converter allows the machine to work worldwide with all power supply systems and enables smooth start and enhanced motor protection. | |||||||

Polishing is a value-added operation in stainless steel fabrication. The highest possible degree of surface finish is usually desirable