News & Media

Contacts

-

Valgro India Limited (HO)

Valgro House, 2nd Floor,

Shailly Square,Virat Nagar,

Ahmedabad, 382415

Gujarat. India - +91 90990 79325

- sales@valgroabrasives.com

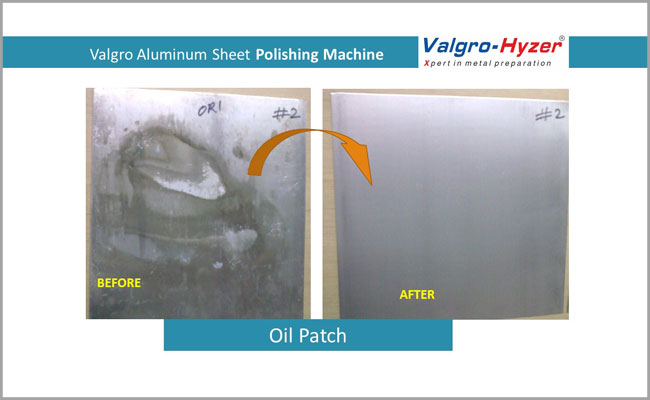

Valgro Aluminium sheet polishing machine is used to have brush finish, hairline, and matt finish before anodizing. Abrasive Brushes clean the surface of the aluminum and eliminate scratches, marks, foreign particles, and other residue. The etching duration of satin-brushed aluminum prior to anodizing is much less than the un-brushed counterparts resulting in less chemical consumption in etching and wastewater treatment, therefore a considerable decrease in production costs.

The obtained finish is of fine mechanical satin type, with excellent appearance like Scotch-Brite. Different type of abrasive grit brush offers smooth and uniform brush effect with dry process.

| Model "Fabrika" | DB-24 | DB-24 HD | DB 32 | DB 32 HD | DB 50-1HD | DB 62-1HD | ||

|---|---|---|---|---|---|---|---|---|

| Head Type | Roller Brush | Roller Brush | Roller Brush | Roller Brush | Roller Brush | Roller Brush | ||

| Work Surface | Top Side | Top Side | Top Side | Top Side | Top Side | Top Side | ||

| Work Head | 1 | 1 | 1 | 1 | 1 | 1 | ||

| Process: Wet / Dry | Wet / Dry | Wet / Dry | Wet / Dry | Wet / Dry | Wet / Dry | Wet / Dry | ||

| Application | Cleaning + Finishing | Cleaning + Finishing | Cleaning + Finishing | Cleaning + Finishing | Cleaning + Finishing | Cleaning + Finishing | ||

| Finish Achieved | Brush Finish | Brush Finish | Brush Finish | Brush Finish | Brush Finish | Brush Finish | ||

| Type of Material | Aluminum | Aluminum | Aluminum | Aluminum | Aluminum | Aluminum | ||

| Min. Max Width | 25-600 | 25-600 | 25-800 | 25-800 | 1000-1250 | 1000 - 1550 | ||

| Min. Length | 150 | 250 | 250 | 350 | 1000 | 1000 | ||

| Min. Max Thickness | 0.8 to 3 | 0.8 to 3 | 0.8 to 3 | 0.8 to 3 | 0.8 to 3 | 0.8 to 3 | ||

| Brush Diameter | 125 | 225 | 225 | 300 | 350 | 350 | ||

| Brush Action R = Rotate O = Oscillate | R + O | R + O | R + O | R + O | R + O | R + O | ||

| Conveyor Type R= Roller / B = Belt | Roller | Roller | Roller | Roller | Roller | Roller | ||

| Conveyor speed Min / Max - MPM | 0.5 - 10 | 0.5 - 10 | 0.5 - 10 | 0.5 - 10 | 0.5 - 10 | 0.5 - 10 | ||

| Dust Extraction Model No | DCS-3 | DCS-3 | DCS-3 | DCS-3 | DCS-5 | DCS-5 | ||

| Electrical parameters | The integrated frequency converter allows the machine to work worldwide with all power supply systems and enables smooth start and enhanced motor protection. | |||||||

The highest possible degree of surface finish is usually desirable, for two quite distinct reasons.