News & Media

Contacts

-

Valgro India Limited (HO)

Valgro House, 2nd Floor,

Shailly Square,Virat Nagar,

Ahmedabad, 382415

Gujarat. India - +91 90990 79325

- sales@valgroabrasives.com

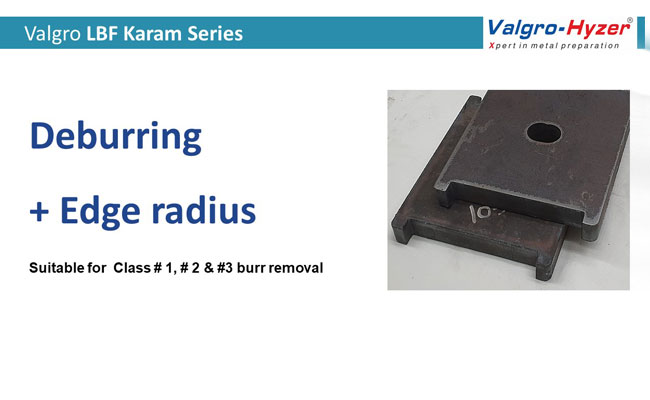

The Valgro LBF Karma Series can be used for plasma and laser cut flat parts for various applications such as deburring, edge rounding. Valgro Karma series is available in various configurations including Belt + Brush, Belt + Disc, Belt + Brush + Disc,

VALGRO long belt finishing machines have a flexible abrasive belt that enables finishing on flat surfaces of big dimensions. VALGRO-LBF KARAM machine is ideal for Hot and Cold rolled plasma cut parts deburring and grinding.

Valgro LBF Karma series are metal deburring and edge rounding machines for metal sheet parts cut by punching, shearing, laser, or plasma. Removing burrs and creating round edges using an abrasive belt and cross belts. Which supports parts up to 1250x100 mm. Width and on some as small as 50x50 mm. The Inside and outside contours of products made from stainless steel, steel, and aluminum parts cut by laser or other thermal processes are burrs cleaned from the total surface.

| Model KARAM | LBF32-BR | LBF32-BRR | LBF32-BDD | LBF50-BRR | LBF50-BDD | |

|---|---|---|---|---|---|---|

| Head Type Belt / Roller / Disc | B + R | B + R + R | B + D + D | B + R + R | B + D + D | |

| Work Surface | Top Side | Top Side | Top Side | Top Side | Top Side | |

| Process: Wet / Dry | Dry | Dry | Dry | Dry | Dry | |

| Work head | 2 | 3 | 3 | 3 | 3 | |

| Application | Deburring + Edge Rounding | Deburring + Edge Rounding | Deburring + Edge Rounding | Deburring + Edge Rounding | Deburring + Edge Rounding | |

| Finish Achieved | - | - | - | - | - | |

| Burr Qualification | Class 1,2,3 | Class 1,2,3 | Class 1,2,3 | Class 1,2,3 | Class 1,2,3 | |

| Type of Material | Carbon steel | Carbon steel | Carbon steel | Carbon steel | Carbon steel | |

| Min. Max Width | 50-800 | 50-800 | 50-800 | 50-1250 | 50-1250 | |

| Min. Length | 100 | 100 | 100 | 100 | 100 | |

| Min. Max Thickness | 3-100 | 3-100 | 3-100 | 3-100 | 3-100 | |

| Weight of capacity | 100kg | 100kg | 100kg | 200kg | 200kg | |

| Abrasive Belt width | 125 | 125 | 125 | 125 | 125 | |

| Abrasive Belt Size | - | - | - | - | - | |

| Roller Brush Diameter | 225 | 225 | - | 225 | - | |

| Disc Brush Diameter | - | - | 200 | - | 200 | |

| Brush Action R = Rotate O = Oscillate | R + O | R + O | R + O | R + O | R + O | |

| Conveyor Type R= Roller / B = Belt | Belt | Belt | Belt | Belt | Belt | |

| Conveyor speed MPM Min / Max | 0.5 - 10 | 0.5 - 10 | 0.5 - 10 | 0.5 - 10 | 0.5 - 10 | |

| Dust Extraction Model No | DCS-3 | DCS-3 | DCS-3 | DCS-5 | DCS-5 | |

| Electrical parameters | The integrated frequency converter allows the machine to work worldwide with all power supply systems and enables smooth start and enhanced motor protection. | |||||

We have a wide range of deburring and Finishing machines for sheet metal processing with One roof Solution.