News & Media

Contacts

-

Valgro India Limited (HO)

Valgro House, 2nd Floor,

Shailly Square,Virat Nagar,

Ahmedabad, 382415

Gujarat. India - +91 90990 79325

- sales@valgroabrasives.com

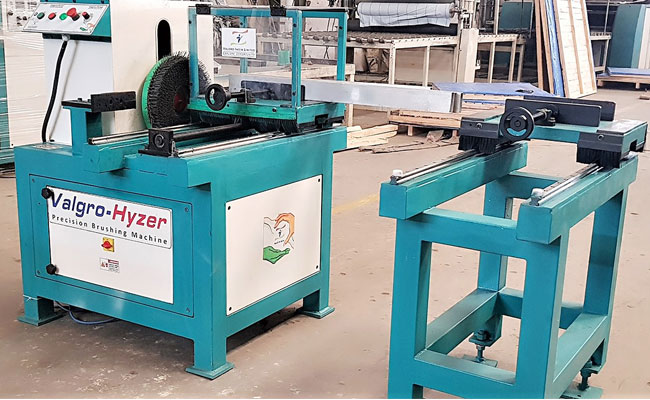

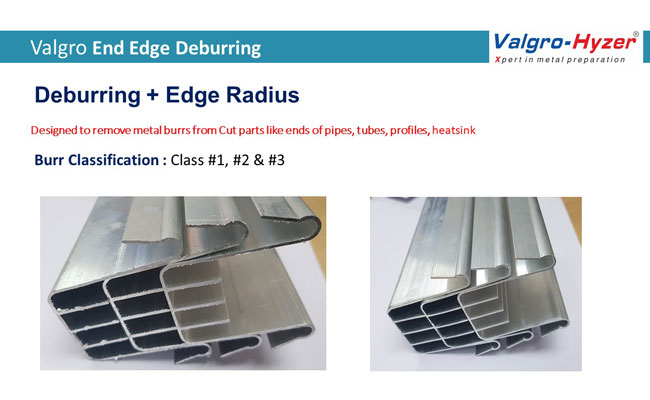

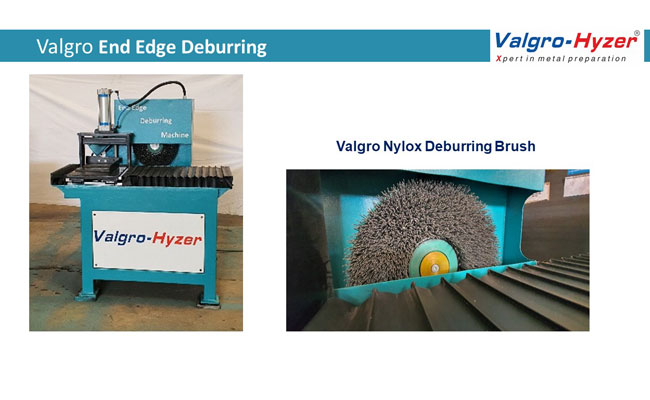

VALGRO-SAMARTH – Edge Breaker Series Tube END EDGE Deburring Machine is designed to remove metal burrs and shear cut edge from ends of pipes, tubes, and profiles. Its single head semi-automatic end edge deburring system helps you to easily activate clamping mechanism. Its automatic clamp shell hood provides additional safety from dust. It drives variable speed with a 2 HP motor attached to 12inches or 14inches Valgro disc deburring brush.

Valgro Profile Tube End Edge Deburring Machine works to deburr round, rectangular, square, and other shape's edges. It is also compatible with many different cut tubes and profile shapes and delivers results in a few seconds and a single operation. The deburring operation can be done simultaneously inside and outside the tube in a single operation without rotating the pipe. The process result is the elimination of burrs getting slightly rounded edges. It can be integrated with a single Head Semi-Automatic End Edge Deburring System. Its automatic clamp shell hood provides added safety and additional dust control.

| Model | EED14-M | EED14 A | EED14BE |

|---|---|---|---|

| Head Type | Wheel / Disc | Wheel / Disc | Wheel / Disc |

| Work Surface | End Edge | End Edge | End Edge - Both Side |

| Work Head | 1 | 1 | 2 |

| Process: Wet / Dry | Dry | Dry | Dry |

| Application | Burr Removal Inside + OutSide | ||

| Finish Achieved | Smooth edge | Smooth edge | Smooth edge |

| Type of Material | Cut Part | Cut Part | Cut Part |

| Burr Classification | Class #1 & Class #2 | ||

| Max Dia | 100 | 100 | 100 |

| Min. Length | 200 | 200 | 200-600 |

| Brush Diameter | 300 / 350 | 300 / 350 | 300 / 350 |

| Brush Action R = Rotate / O = Oscillate | R | R+O | R+O |

| Conveyor Type R= Roller / B = Belt | Manual | Belt | Belt |

| Conveyor speed Min / Max - MPM | Manual Feed | 0.5 - 10 | 0.5 - 10 |

| Dust Extraction : Valgro-Duklean | DCS-1 | DCS-3 | DCS-5 |

| Electrical parameters | The integrated frequency converter allows the machine to work worldwide with all power supply systems and enables smooth start and enhanced motor protection. All Dimensions in MM |

||

We have a wide range of deburring and Finishing machines for sheet metal processing with One roof Solution.