News & Media

Contacts

-

Valgro India Limited (HO)

Valgro House, 2nd Floor,

Shailly Square,Virat Nagar,

Ahmedabad, 382415

Gujarat. India - +91 90990 79325

- sales@valgroabrasives.com

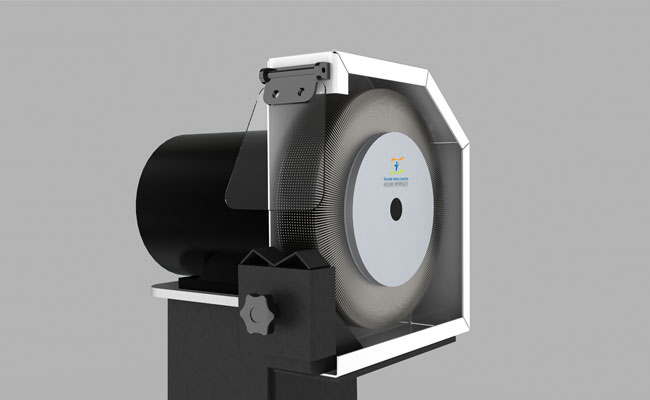

Valgro pipe deburring machine can deburr material from the inside and outside of a pipe at the same time and this significantly reduces time consumption. The machine has a powerful speed motor and the ability to deburr both round and square sections. Deburr material such as steel, aluminium, stainless steel, copper, brass, and the like.

The machine comes with a 0.5mm abrasive wire brush and is prepared for the installation of an extractor as an accessory.

This economic version of deburring machine can also be used in various operations from small workshops to huge factories. Easy and fast deburring off all kinds of profiles (inner borders included) and full materials by steel turning the brush. Driving gear moves 3 brushes and is not adjustable. Suitable for offhand application. In-build burr collection system with all safety features

| Model | PD-50 | ||

|---|---|---|---|

| Head Type | Wheel | ||

| Work Surface | End Edge | ||

| Work Head | 1 | ||

| Process: Wet / Dry | Dry | ||

| Application | Burr Removal Inside + OutSide | ||

| Finish Achieved | Smooth edge | ||

| Type of Material | Cut Part | ||

| Burr Classification | Class #1 & Class #2 | ||

| Max Dia | Ø 50 | ||

| Min. Length | 100 | ||

| Brush Diameter | Ø 250 | ||

| Brush Action R = Rotate / O = Oscillate | R | ||

| Conveyor Type R= Roller / B = Belt | Manual Feed | ||

| Power | 3HP | ||

| Dust Extraction : Valgro-Duklean | DCS-1 | ||

| Electrical parameters | The integrated frequency converter allows the machine to work worldwide with all power supply systems and enables smooth start and enhanced motor protection. All Dimensions in MM |

||

We have a wide range of deburring and Finishing machines for sheet metal processing with One roof Solution.