News & Media

Contacts

-

Valgro India Limited (HO)

Valgro House, 2nd Floor,

Shailly Square,Virat Nagar,

Ahmedabad, 382415

Gujarat. India - +91 90990 79325

- sales@valgroabrasives.com

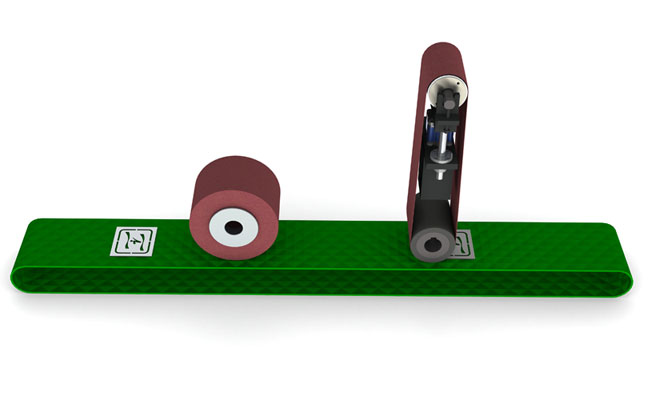

Valgro Copper Busbar Deburring and Polishing Machine with Belt grinding and polishing are very flexible machining processes with undefined cutting edges that use a large number of cutting particles. Depending on the abrasive belt selected, extreme high stock removal rates (1 mm and more per pass ) or super fine finishes can be achieved (Ra 0,1 µm and better).

The abrasive belt unit with a contact drum can be used for graining a decorative straight-line finish or for deburring. Depending on the application the hardness and diameter of the contact drum can be selected accordingly. For example a harder drum is ideal for straigh-line finishing whereas a softer drum works better for deburring.

The belt grinding and belt polishing are both used to improve the finish of flat materials and profiles as well as bars and tubes such as hydraulic, pneumatic and pressure cylinder; Axles, Calender rolls and billets; Engine components, stamped and sintered parts. For scale removal or linishing and sanding before and after coating.

| Model | HYB-06 | HYB -12 |

|---|---|---|

| Head Type | Belt + Brush | Belt + Brush |

| Work Surface | Top Side | Top Side |

| Process: Wet / Dry | Wet / Dry | Wet / Dry |

| Work Head | 1+ | 1+ |

| Application | Sanding + Deburring + Finishing + Brushing | Sanding + Deburring + Finishing + Brushing |

| Finish Achieved | Matt Hairline, #4 | Matt Hairline, #4 |

| Burr Classification | Class 1,2,3 | Class 1,2,3 |

| Type of Material | Stainless Steel | Stainless Steel |

| Max Width | 150 | 300 |

| Min. Length | 200 | 220 |

| Min. Max Thickness | 0.5 - 3mm / 1 to 50mm | 0.5 - 3mm / 1 to 50mm |

| Weight of capacity kg | 100 | 100 |

| Drum Diameter | 150 | 150 |

| Brush Diameter | 225 | 225 |

| Abrasive belt Size (MM) | 150 x 1250 | 300 x 1250 |

| Brush Action R = Rotate O = Oscillate |

R + O | R + O |

| Conveyor Type R= Roller / B = Belt |

Belt | Belt |

| Conveyor Bed | Grip Roll | Grip Roll |

| Conveyor speed Min / Max - MPM |

0.5 - 10 | 0.5 - 10 |

| Dust Extraction Model No |

DCS-1 | DCS-1 |

| Electrical parameters | The integrated frequency converter allows the machine to work worldwide with all power supply systems and enables smooth start and enhanced motor protection. | |

We have a wide range of deburring and Finishing machines for sheet metal processing with One roof Solution.