News & Media

Contacts

-

Valgro India Limited (HO)

Valgro House, 2nd Floor,

Shailly Square,Virat Nagar,

Ahmedabad, 382415

Gujarat. India - +91 90990 79325

- sales@valgroabrasives.com

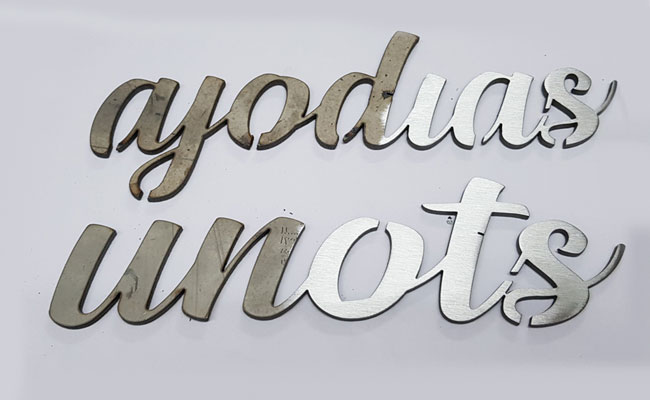

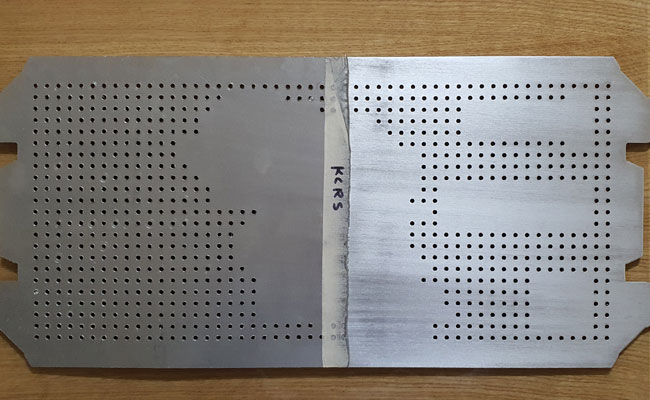

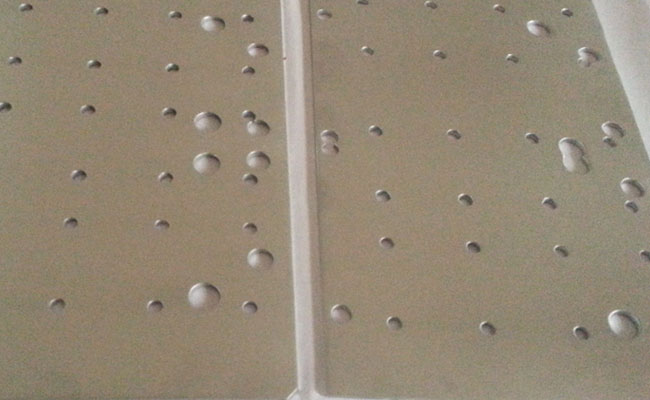

Valgro-Hyzer deburring machine is meant primarily for deburring and cleaning sharp corners, hole edges, and irregular parameters from sheet metal components without damaging the metal surface.

SAMARTH DB Series Flat metal sheet parts deburring is designed for cleaning, deburring, and polishing sharp corners, holes, edges, and varying parameters of the metal sheet parts without damaging the surface. Flat metal sheet parts deburring works with flexibility, which facilitates lower operational costs of your manufacturing unit.

Valgro flat metal sheet parts deburring offers smooth removal of micro scratch, acid layers, and oxide from the surface of the metal sheets. Valgro brushing & deburring machine operation is a safe and economical way, and this machine is more productive than a conventional deburring system and can eliminate manual deburring work. Valgro has developed various models for sheet Deburring in the configuration of flexibility and lower operating costs. Sheet Deburring machines are available for both dry and wet processing.

DB SAMARTH Fabrika series Sheet Deburring machine is widely accepted at sheet metal fabrication Industries

| Model | DB-24 | DB-24 HD | DB 32 | DB 32 HD | DB 50 HD | DB 62 HD |

|---|---|---|---|---|---|---|

| Head Type | Roller Brush | Roller Brush | Roller Brush | Roller Brush | Roller Brush | Roller Brush |

| Work Surface | Top Side | Top Side | Top Side | Top Side | Top Side | Top Side |

| Work Head | 1 | 1 | 1 | 1 | 1 | 1 |

| Process: Wet / Dry | Dry | Dry | Dry | Dry | Dry | Dry |

| Application | Deburring + Finishing + Cleaning | |||||

| Finish Achieved | Brush # 4 | Brush # 4 | Brush # 4 | Brush # 4 | Brush # 4 | Brush # 4 |

| Burr Class Qualification | Class 1 & 2 | Class 1 & 2 | Class 1 & 2 | Class 1 & 2 | Class 1 & 2 | Class 1 & 2 |

| Type of Material | Aluminium / Sgtainless Steel / Brass / Copper | |||||

| Min. Max Width | 25-600 | 25-600 | 25-800 | 25-800 | 400-1250 | 400-1550 |

| Min. Length | 175 | 275 | 275 | 350 | 800 | 800 |

| Min. Max Thickness | 0.8 to 3 | 0.8 to 3 | 0.8 to 3 | 0.8 to 3 | 0.8 to 3 | 0.8 to 3 |

| Brush Diameter | 125 | 225 | 225 | 300 | 350 | 350 |

| Brush Action Rotate / Oscilate | R + O | R + O | R + O | R + O | R + O | R + O |

| Conveyor Type R= Roller / B = Belt | Roller | Roller | Roller | Roller | Roller | Roller |

| Conveyor speed Min / Max - MPM | 0.5 - 10 | 0.5 - 10 | 0.5 - 10 | 0.5 - 10 | 0.5 - 10 | 0.5 - 10 |

| Dust Extraction Model No | Duklean DCS-3 | Duklean DCS-3 | Duklean DCS-3 | Duklean DCS-3 | Duklean DCS-5 | Duklean DCS-5 |

| Electrical parameters | The integrated frequency converter allows the machine to work worldwide with all power supply systems and enables smooth start and enhanced motor protection. | |||||

We have a wide range of deburring and Finishing machines for sheet metal processing with One roof Solution.